Precision Industrial Metrology Services

Learn MoreLaser Tracker

Using the latest in Laser Tracker technology, we provide premier alignment and dimensional inspection services with precision and repeatability.

View Details

Scan-Arm

We provide 3D Laser Scanning services for inspection and reverse engineering purposes. This is a great option for inspecting parts that cannot be measured using traditional methods.

View Details

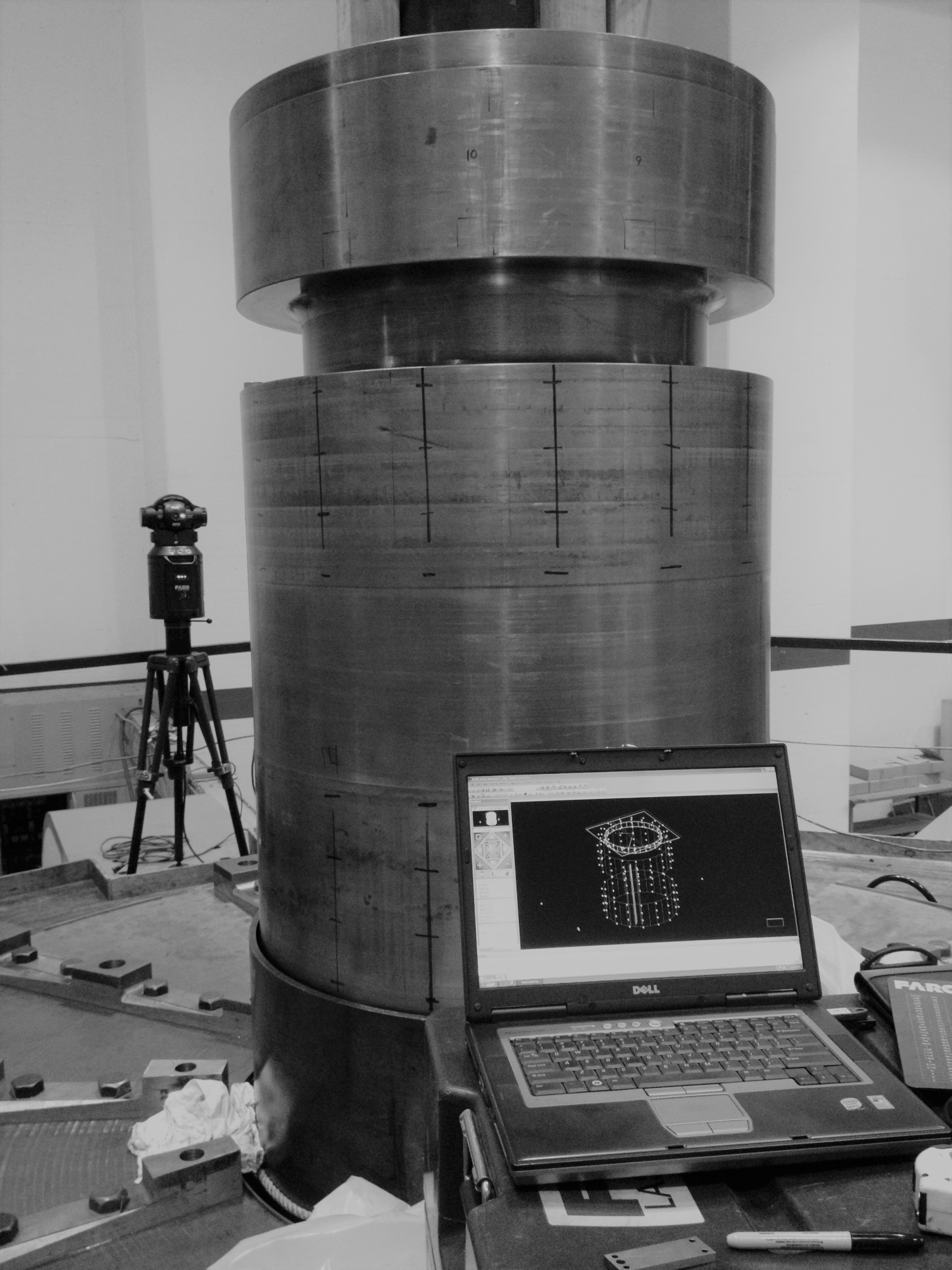

Hydroelectric Shaft Alignment

We can measure and assist in the alignment of hydroelectric shaft runout, plumbness and straightness as well as provide thrust bearing correction information.

View Details

Precise Flatness Inspection

Using a Planekator, we are able to inspect the flatness of hydroelectric thrust runners, thrust collars and spring beds onsite to a very high degree of accuracy.

View Details

Connect With Us

If you would like to learn more about how we can assist in the success of your project, please contact us.

CONNECT